06 November 2023

ESCO (Energy reduction Support & Collaboration) is the energy-supporting function of Toyota Motor Manufacturing UK, with a remit to manage utilities and consumption, which is done in two ways: using Kaizen, a Continuous Improvement concept and foundation of lean manufacturing; and abnormality management.

Saving energy wirelessly

One of its tasks is to find out when too much energy is being consumed, either through abnormality or through equipment not being turned off.

The company is focusing on meeting its 2030 milestone target, part of the Toyota Environmental Challenge 2050, to become a net-zero business. Monitoring and managing energy consumption is a big part of this agenda. Cost savings are also key given the rapidly increasing rise in energy prices.

ESCO has a challenge to reduce the utilities cost required to produce a vehicle by 2% year on year, which through volume increase changed to 7.5%. In 2020 the group identified which equipment consumes most energy at transformer level, but couldn’t see the granular detail, i.e. whether each piece of equipment was operating at its optimum and expected level. With multiple production zones at the site, monitors had to cover thousands of square metres with many obstacles to their signal. Finally, the monitoring solution over such a vast area had to be cost-effective in both product and installation time and cost.

The company wants to be able to view every piece of equipment’s energy consumption and condition in real-time.

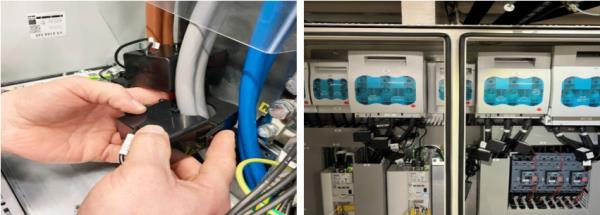

Non-intrusive installation

The Toyota team trialled Pressac’s wireless current monitoring sensors to monitor energy consumption and machine condition and was impressed by the lack of intervention and maintenance needed for the equipment (wireless, self-powered CT sensors simply clamp around power cable). The installation of sensors was smooth, without any production downtime. Pressac also advised how to set up initial visualisation of data.

ESCO uses a modular system called Ignition, which includes built-in MQTT, a standard messaging protocol for the Internet of Things. They established that Pressac’s sensors would integrate well with this system. The ease of use, cost viability and quick installation ticked all the boxes they were looking for.

Toyota has currently fitted around 300 wireless current sensors to energy-intensive key significant equipment, such as painting ovens. They have also been installed on lower-level kit, which were more unknown entities in terms of energy consumption. From here, they have created an energy map of different aspects of their production process.

Additionally, they have installed pulse counters to understand gas consumption, as well as CO2, temperature, and humidity sensors to monitor status on the shop floor and keep optimal indoor air quality conditions for team members through HVAC systems.

Real-time visualisation

The team has been able to create a highly detailed view of not just each type of equipment fitted with sensors, but each individual control panel. For example, one injector moulder purely used for service parts was identified as ticking over at a high-power level. This has now been modified, still ticking over to keep it fully functional but no longer consuming energy when not needed. Savings on this piece of kit alone has seen energy consumption in non-production periods reduced by 82%.

This type of energy monitoring can now be done for all pieces of equipment with the CT sensors, with the team able to break down into patterns, e.g. if one shift is turning off equipment and another isn’t.

“The big advantage of using the Pressac current sensors is the simplicity and increased safety of non-intrusive installation,” said Graham Lane, ESCO group leader, Toyota Motor Manufacturing UK.

Although the initial aim was for energy consumption, the team soon realised that the granular monitoring would help with the tandem aim of spotting abnormalities. In fact, the first area to benefit from monitoring was the water farm in 2020. The sensors highlighted a failing inverter — an abnormality — which meant the team could perform an early intervention to replace the part, preventing a shutdown and huge production impact.

The ESCO team’s Energy Reduction Kaizen has increased by 100% since the installation due to the ability to identify opportunities through real-time visualisation. They have overachieved their targets for savings-per-vehicle, with significant further potential savings ahead. The investment in Pressac technology and the Ignite platform has yielded a return of 1,900% so far.

“If we look back five years, small improvements may not have been as impactful as they are today. All energy consumption savings are taking us a step further towards our carbon-neutral ambition,” said Lane. “Skyrocketing energy costs also means that little interventions can have hugely beneficial results. Going forward we’d like to have every single piece of kit covered, to give us a complete model of the whole production process and identify where we can make even more energy savings.”